|

IPaper

Knowledge Center Report

RFID, which is an acronym for Radio Frequency Identification, is not a new

technology. It was first used in the late 1960's, but it has only become more

widespread with advances in technology.

RFID Systems consist of a transponder, also known as a tag, which is basically

a microchip connected to an antenna. The tag is mounted to an item, such as

a pallet of goods in a warehouse, and a device called a reader communicates

with the tag via radio waves. Depending on the type of tag that is used, the

reader can receive detailed information or it can receive data as simple as

an identification number.

RFID is similar to barcode systems in which data, such as a price, is accessed

when the barcode is read. The main difference is that the barcode must come

in direct contact to an optical scanner/reader and the RFID tag can transmit

to the reader via radio waves and does not have to be in direct contact. An

RFID reader can receive data from as many as 1,000 tags per second.

The radio signals can go through many non-metallic substances such as rain,

fog, snows, dirt and grime, painted surfaces, etc. This gives RFID tags a distinct

advantage over optically read items, such as barcodes, which would be useless

under similar conditions.

The many uses for RFID technology include:

- Smart labels and security labels

- Product and inventory management

- RFID chips in car keys for security

- Theft control

- Placement on pharmaceuticals to prevent counterfeited drugs from entering

the legal supply chain

- Increased efficiency in admissions into entertainment or sporting events

- Increased efficiency in toll road payments

- Monitoring the whereabouts of luggage, library books, livestock, etc.

It is predicted that RFID use will continue to increase. It is unlikely to

ever be as cost-effective as barcoding, but it will become dominant in areas

where barcoding and other optically read technologies are not effective.

RFID Tag Categories

The basic types of RFID tags can be classified as read/write and read only.

The data stored on read/write tags can be edited, added to, or completely rewritten,

but only if the tag is within the range of the reader. The data stored on a

read only tag can be read, but cannot be edited in any way. Read/write tags

are much more expensive than read only tags, so they are not used for tracking

most commodity items.

RFID tags are further categorized as:

- Active tags, which contain a battery that powers the microchip and allows

it to transmit a signal to the reader.

- Semi-active (or semi-passive) tags, which contain a battery to run the circuitry

of the chip, but must draw power from the magnetic field created by the reader

in order to communicate with the reader.

- Passive tags, which rely solely on the magnetic field created by the radio

waves sent out by the reader to create a current that can be received by the

antenna within the passive tag.

RFID Construction

RFID Tag Components

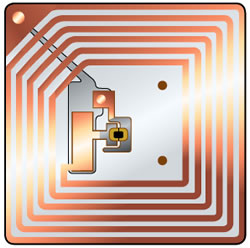

RFID tags consist of a microchip connected to an antenna, which is constructed

of a small coil of wires. The assembly is usually covered with a protective

layer (such as a laminated card), which is determined by the type of application.

The RFID tag can be a passive tag or an active tag. The RFID tag is also known

as an inlay.

Components of passive RFID system:

- An antenna is attached to a microchip.

- The antenna allows the chip to transmit information to a reader, which

also has an antenna.

- The reader is the device that actually sends out the radio waves to create

a magnetic field. A passive RFID tag draws its power from this magnetic

field, which powers the circuits in the microchip allowing it to transmit

data back to the reader.

- Reader transmits to a computer system.

- The computer passes data onto a network.

- Software determines how the data received should be used.

Microchip

The most expensive read/write, active RFID transponders may have microchips

with a memory capacity of up to one megabyte (1,000,000 characters). Most

tags are inexpensive, passive transponders that can store only 32 to 128

bits (characters) of information or less, so an identification number is

basically the only data that the read-only tag will contain. When the number

is read, detailed information stored in a database in a computer can be

accessed. This is similar to a barcode system in which data, such as a price,

is accessed when the barcode is read. The main difference is that the barcode

must come in direct contact to an optical scanner/reader and the RFID tag

can transmit to the reader via radio waves and does not have to be in direct

contact.

Antenna

The antenna allows the chip to receive and relay information, such as an

ID number of an individual product. Some antennas are constructed of metal

and are etched or stamped from metal, such as copper. Other types of antennas

are printed. Advances in technology are allowing printed antennas to achieve

the functionality of traditional materials and printed antennas are less

expensive. One of the most popular methods of printing antennae is with

the use of silver conductive inks printed on plastics substrates or paper.

Testing of RFID antennae is usually performed with ohmmeters, milliohm meters,

RF network analyzers, impedance-measuring equipment, and others.

RFID Tag Shapes and Sizes

RFID tags can be manufactured in several different shapes and sizes depending

on the type of application in which they will be used.

- Some are the size of a pencil lead or are less than a half-inch in length

and can be inserted under the skin of animals and livestock.

- Screw-shaped tags are used to identify specific trees.

- Rectangular RFID tags found in some products are used as an anti-theft device.

- Large, heavy duty tags that are several inches in length, width, and depth

are used to track large containers or large vehicles such as trucks or rail

cars.

Radio Frequencies

RFID tags operate under different radio frequencies, depending on the application.

The FCC of the US government determines the limits on power output of RFID systems

as well as the different radio frequencies that can be used. Low, high, and

ultra-high (UHF) frequencies are used with RFID transponders.

- Low and high frequency tags are less expensive than UHF and are best used

for merchandise tracking, animal and livestock identification, and security

access.

- Tags with UHF frequencies use more power than low and high frequency tags,

but they have a greater range and the data transfer rate is faster. They are

best suited for applications in which the tag and the reader have a more direct

path with one another. Rail car tracking and automated toll booths are some

of the uses.

The communication range between the RFID tag and the reader depends on the

frequency, the antenna size of the tag, the antenna size of the reader, and

the output power.

- Low and high frequency devices have communication ranges of a few inches

to several feet, depending on the application.

- Ultra-high (UHF) may have ranges of 25 feet or more.

The radio signals can go through many substances such as rain, fog, snows,

dirt and grime, painted surfaces, etc. This gives RFID tags a distinct advantage

over optically read items, such as barcodes, which would be useless under similar

conditions. An RFID reader can receive data from as many as 1,000 tags per second.

Quality Control

Quality control is a necessity because groups of manufactured inlays may have

experienced some damage before they reach the printer or converter. The chips

in the inlays can also be damaged during the printing or converting process,

which renders the RFID tag useless. Special substrates can be used to limit

the damage to the chips. Quality control after printing or converting is also

important to ensure that none of the chips were damaged and will all be functional.

When RFID antennae are manufactured, they are usually tested with ohmmeters,

milliohm meters, RF network analyzers, and impedance-measuring equipment. It

is also important to remember that RFIDs are electronic devices and therefore

should not be exposed to or stored near areas containing large amounts of electromagnetic

or static energy.

Applications

The three most common uses for RFID tags are:

- Tracking items in production lines

- Tracking items in supply chains

- Enhancing security measures

In other industrial uses, tags attached to items for tracking during assembly

or manufacture must be able to withstand heat, cold, etching processes, cleaning

and degreasing procedures, moisture, dirt, and many other types of conditions

and environments that would not be suitable for optically or magnetically read

devices.

Printing

With most types of printed applications, such as labels, the user is unaware

of the existence of the chip and antenna because of the different methods of

concealing them on the document. Some printers (such as label printers) purchase

inlays (containing the RFID) that are already manufactured and then incorporate

them into their printed products.

Label Printing

Label printing is one of the fastest growing segments of the printing industry

using RFID technology. Smart labels and electronic surveillance labels are

being used for applications in which simple, optically read barcoding may

not be suitable.

Smart Labels

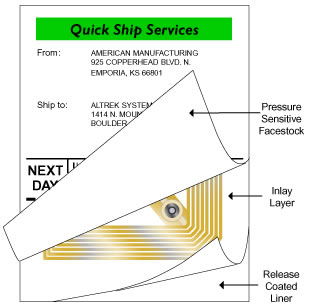

Smart labels contain RFID transponders to automatically capture data. The

standard construction of a smart label consists of a pressure sensitive

facestock, an inlay, which contains the radio frequency identification transponder,

and a liner. The inlay is laminated between the facestock and the liner.

The transponder contains an antenna and microchip.

The data from the smart label is accessed when the transponder passes by

the reader. Radio wave lengths are picked up from the antenna and the data

on the microchip is transferred to the reader and then passed on to a computer

or printer. As the product moves from one stage to the next, its movements

can be monitored and data can be updated when necessary. The smart label

can identify, track in real-time, and authenticate a product.

Smart labels are used on all types of applications including supply chain

management, production control, work-in-process, baggage identification

and tracking, express delivery services, reusable container tracking, and

security systems.

Equipment is available that is able to encode a separate RFID inlay and

then bond it to the substrate after the label has been printed. A variety

of label substrates can be used. This process eliminates the need for inserting

transponders into blank label stock before the label stock is printed. Since

the printing process can damage stock containing transponders, the process

eliminates this problem by allowing the printing to happen first. The system

creates a printing system that is on-demand. There is no need for special

papers because the equipment can print on almost any label stock.

Other equipment is able to encode data on very thin UHF RFID transponders

that are inserted into smart labels. The equipment immediately verifies

the proper encoding. The equipment can then print text, graphics, or barcodes

on the smart label to complete the application. The smart labels can be

used for a number of warehousing, inventory, and supply chain tracking applications.

There are also compact desktop printers specifically design for RFID printing.

The printers can read, write, and print labels that have an embedded RFID

transponder.

The industry acceptance of smart labels has been slow. The RFID technology

can improve performance and efficiency but is expensive to startup. As more

companies commit to the use of this new technology it will become more widely

accepted and many will benefit from its capabilities.

Electronic Article Surveillance (EAS) Labels

EAS labels are used as anti-theft devices. The label is used with EAS monitoring

equipment to detect if an item is being removed without authorization. The

EAS systems are used in retail stores, data centers, and libraries. When

applied to products, the EAS label is capable of activating an alarm as

it passes through an electronic surveillance detector, such as those found

in retail store exits. When the product is purchased, the label is made

inactive by the use of a deactivation device at the checkout station. Once

the label is deactivated it is referred to as a "dead label".

Labels that have not been deactivated are referred to as "live labels".

RFID is only one of the technologies used for EAS labels. Other common

types are AM (Acousto Magnetic) and EM (Electro Magnetic). Each of the EAS

systems has its own unique detection equipment that must be used to allow

the system to work properly.

Because of the anti-theft protection they provide, the EAS labels and EAS

systems allow more freedom for retail stores to display items that would

usually be locked in display cases. This allows the consumer to examine

the product more closely before purchasing.

Comparisons with Barcoding

RFID and barcode technology are similar in concept, but the two technologies

have different methods for reading data. RFID reads data via radio waves and

does not need a direct line of sight between the reader and the tag. Barcodes

are read optically and do require a direct line of sight between the reader

and the barcode.

Advantages of RFID systems over barcodes:

- It is not necessary to have a line of sight between the RFID tag and

the reader as there is with a barcode and scanner.

- Information can be rewritten to the tag without having to see the tag.

This is true even if the tag is mixed into other items that have been

tagged.

- Nearly 100% of RFID tags are readable, unlike items that contain a printed

barcode, which can become damaged with improper handling.

- The potential problems associated with substandard print quality of

barcodes, which in turn leads to scanning and reading problems, are eliminated.

Other points to consider:

- Barcodes are universally accepted because they are very inexpensive

and there are established standards for their use. RFID technology is

more expensive and has fewer universal standards in the way they are used.

- Even if RFID technology becomes as widespread as barcoding, it will

not totally replace the universally accepted barcode technology.

Other Print/Security Applications

Besides the various types of RFID labels that are being printed for product

tracking and security, plastic cards and badges embedded with RFID transponders

are being produced. Data from identification cards embedded with RFID tags

can be read as people pass through a doorway. RFID tags embedded in security

badges offer an alternative method for controlling access to sensitive information

or limiting access to specific areas.

Merchandise/Inventory Tracking

When used with product and inventory control, a computer keeps track of the

data received from the transponders/tags through the reader and can trigger

reorders based on the adjusted inventory levels. Antennas can be built into

warehouse doorframes in order to receive data as merchandise, cartons, and pallets

of goods containing an RFID tag pass, through the doorway.

RFID costs may not become low enough for the tags to be used on all types of

products and services. It may not be cost effective to include the tags with

every item if the items are inexpensive commodity items, but the tags can be

very useful to track full pallets of commodities for inventory control.

Transportation

RFID tags can be used for a number of applications in the transportation industry

for monitoring and tracking of vehicles and products.

Railroads

RFID systems can be configured for rail car identification:

- The tags are installed underneath the rail cars.

- The antennae are mounted between or near the tracks.

- The readers are usually located in a building no more than 100 feet away.

Trucking

Commercial trucking facilities also use RFID systems to monitor truck movements

in and out of a main terminal.

Automotive

RFID systems are very useful in the automobile manufacturing industry in

tracking individual vehicles through the assembly process. RFID systems are

also being installed in toll booths to monitor the traffic.

Airports

Most airports track passenger baggage with barcoded labels or tags, but they

are often damaged do to rough handling of the baggage. Barcoded tags that

have been damaged because of rough baggage handling, may account for 10% of

the total volume. All of these bags must be accounted for manually, which

can be a time consuming process. RFID systems can help to eliminate the problems

that occur with unreadable barcodes.

When used for tracking bags at an airport, RFID tags contain a unique number

assigned to the bag. Anyone with access to a reader could see the number,

but any personal information could not be viewed because it is stored in a

database and is not stored on the tag.

Privacy Issues

Many people mistakenly believe that RFID is similar to GPS (Global Positioning

System) and can be used for detailed tracking, but RFID has a range of only

a few feet so this isn't possible. Another misconception that people have is

that the movement of products with RFID tags can be tracked even after the product

is purchased. Most active RFID tags have a read range of about 25 feet, which

means the RFID is basically useless outside of the retail store or business.

Security measures and safeguards used to protect consumer privacy when using

RFID systems:

- The risk of spying or intercepting data that is transmitted via radio waves

is reduced with the use of data encryption and over the air protocols.

- The protocols require both the reader and the eavesdropper to be within

range of the tag.

- The reader changes radio frequencies rapidly and at random, so it is difficult

for a potential eavesdropper to follow the reader.

- Although it is possible for tags to be counterfeited, it is not very practical

because of built-in safeguards, such as the ability of the RFID readers to

verify authenticity of the tags.

Chipless RFID Technology

Systems are now available that provide RFID technology for printed

documents without the need for a microchip. Some of the systems involve the

use of aluminum fibers, which are embedded into paper or packaging materials.

The fibers reflect a signal, which are interpreted as data in a computer.

Another chipless system involves the use of materials made up of very small

chemical particles that possess varying degrees of magnetism. The chemical particles

become active when exposed to the electromagnetic waves from a reader. Each

of the chemicals emits a unique signal that is received by the reader, which

interprets the signal as a binary number. The system uses as many as 70 different

chemicals, so there are 70 different signals. Each chemical has a specific position

in the 70-digit number, which means that a unique binary number can be assigned

to a document based on the mixture of chemicals that are used.

The small particles can be embedded in paper or they can be printed onto paper

or almost any type of substrate. Printed barcodes can be created, which can

be scanned from up to 10 feet away without the need for the barcode to be in

line of sight of the reader. With slight modifications, this technology can

be used with existing barcode systems, which helps to hold down the cost. Major

upgrades of equipment are not necessary. The only areas where the system does

not work very well are in areas containing large quantities of water or metal

objects. Water absorbs RF signals and large quantities of metal reflect the

signals.

Other security measures that can be used in conjunction with the system are:

- Photocopiers can be fitted with readers to prevent unauthorized copying.

- Some applications could require that a document be photocopied onto the

same type of paper.

- Any institution wishing to protect documents could install readers at all

exit points in the building, which would detect if any unauthorized persons

were trying to leave the building with an original or copied document.

- The system can also be used for counterfeit prevention and for tracking

manufactured products.

RFID tattoos for tracking cows... and people

By Thomas Ricker

Did

you know that Saint Louis based Somark Innovations successfully tested

an "RFID tattoo" on cows and rats? Yes indeed, tattoo, not the ol' RFID

chip found in passports, dogs,

and Dutch VIP clubbers. Somark's system uses an array of needles to

inject a passive RFID ink which can be read through the hair on your

choice of beast. The ink can be either invisible or colored but Somark

is keeping mum as to its exact contents. They only say that it doesn't

contain any metals and is 100% biocompatible and chemically inert. The

tattoo can be applied in 5 to 10 seconds with no shaving involved and

can be read from up to 4 feet away -- the bigger the tattoo, the more

information stored. Best of it all, it's apparently safe for humans to

ingest allowing the FDA to track back Mad Cow Disease, e-coli

outbreaks, and Soylent Green. Don't worry, they can't track you

just as long as you chew your food like mama taught. However, with

"military personnel" listed as Somark's "secondary target market,"

well, it's just a matter of time before we're all cattle now isn't it.

VeriChip Wants To Test Human Implantable RFID On Military

By K.C. Jones

TechWeb

:

Aug 23, 2006

VeriChip is pitching its human implantable RFID chips to the U.S. military.

VeriChip spokesperson Nicole Philbin confirmed Wednesday that the company's Board Chairman Scott Silverman has held informal meetings with U.S. Navy and Air Force leaders to suggest a feasibility study of its VeriMed system.

The system relies on an implant the size of a grain of rice, which VeriChip claims has an encrypted 16-digit identification number. Philbin said only proprietary RFID readers can decipher the number, which is then entered into a secure database. A login name and password are required to access the database on a secure Web site, Philbin said, adding that the system is more secure and more effective than things people normally carry in their wallets.

Like overall participation, the amount of information attached to the identification number is at the discretion of individuals who volunteer for the program, Philbin said. That could be limited to the most basic information, like name and telephone number, or it could contain advance directives, organ donor status and more.

VeriChip is owned by Applied Digital, which lists federal agencies among its clients. The company markets the VeriMed system as a way to ensure that emergency responders and healthcare providers can identify a patient who is or unable to communicate and learn of allergies and medical conditions.

"The Department of Defense already has an electronic health records program, and VeriChip would like to enhance the quality of care for vets and military members," Philbin said. "There is no power source. It can't be tracked. It's not a GPS device. It contains no information other than the identification number. It's not mandatory. If a person with the device is presented to an emergency room unconscious, they may be allergic to something or have a preexisting condition, and that information is crucial."

The RFID implants were approved as Class II medical devices by the U.S. Food and Drug Administration in October 2004. In a letter, Donna-Bea Tillman, PhD, director of the F.D.A.'s Office of Device Evaluation, Center for Devices and Radiological Health, outlined potential health risks associated with VeriChip implants. They include adverse tissue reaction; migration of implanted transponder; compromised information security; failure of implanted transponder, inserter or electronic scanner; electromagnetic interference; electrical hazards; magnetic resonance imaging incompatibility; and needle stick.

"With any F.D.A. approval, they state the potential risks," Philbin said. "The F.D.A. is satisfied with the product and that's why they have given it the O.K."

Some people have implanted chips in themselves to experiment with the technology and for fast access to their computer accounts.

Critics contend that VeriChip is peddling its products to governments, while targeting vulnerable populations " like the elderly, inmates, immigrants and members of the military, who have less choice than the general population. They claim that RFID proponents' eventual goal is to "chip" as many people as possible, then track consumers and their behaviors for marketing purposes.

The Electronic Privacy Information Center states that "the ability to track people, products, vehicles, and even currency would create an Orwellian world where law enforcement officials and nosy retailers could read the contents of a handbag perhaps without a person's knowledge simply by installing RFID readers nearby."

"Such a fear is not unfounded. Currently, some RFID readers have the capacity to read data transmitted by many different RFID tags," the organization states on its Web site. "This means that if a person enters a store carrying several RFID tags for example, in articles of clothing or cards carried in a wallet one RFID reader can read the data emitted by all of the tags, and not simply the signal relayed by in-store products. This capacity enables retailers with RFID readers to compile a more complete profile of shoppers than would be possible by simply scanning the bar codes of products a consumer purchases."

Some people have claimed to clone implants, saying that demonstrates how vulnerable they are, but Philbin said they are impossible to clone.

"The company can't verify what hackers claim they can or cannot do," she said.

Joe Davis, spokesperson for the Veterans of Foreign Wars office in Washington, D.C., said although it makes great sense to be able to scan a device and pull up a full medical history, he would like to see further study before the military uses the implants. He said his initial concerns include possible health effects, whether enemies could access soldiers' information and whether the implants would replace dog tags, and, if so, stand up to an explosion.

"They issue two dog tags," he said. "One goes around the neck and the other is laced into the boot. The foot and boot will survive an explosion. DNA from the foot in the boot will survive, plus you've got your metal dog tag right there. What type of survival rate does this little chip have in an explosion? From what I've read, it sounds like they're trying to push this thing through. You don't push things through when it's new technology. You have to weigh all the pros and cons, and you have to ask the service members 'What do you think of this?' because it's going in their neck, or wherever it's going to go, and this proposal needs lot more study."

National Guard orders portable RFID kits

By Patience Wait, GCN Staff

The U.S. National Guard has purchased $4.6 million worth of mobile radio-frequency identification (RFID) systems to improve real-time tracking of supplies at National Guard armories and for deployed operations.

The contracts were awarded to Savi Technology, a wholly owned subsidiary of Lockheed Martin Co. in Bethesda, Md.

Under the contracts, each state's Joint Force headquarters, as well as National Guard units in the District of Columbia, Guam, Puerto Rico and the U.S. Virgin Islands, will receive portable deployment kits (PDKs) and related equipment. The initial orders will provide 54 PDKs, 5,400 active RFID tags and 120 mobile handheld readers, in addition to associated training for National Guard logisticians nationwide. Mission applications include disaster relief, homeland security and other emergency efforts.

The suitcase-sized PDK is an advanced mobile chokepoint solution that integrates several automatic identification and data collection technologies, including bar codes, 2D bar codes, active RFID and GPS location with satellite communications, in a single carrying case. The PDK is fully configurable and quickly operational, with no additional software configuration required.

By embedding the RFID tags in supplies and equipment and using the portable kits, Guard units will be able to communicate with the Defense Department�s global In-Transit Visibility cargo tracking network, giving the National Guard mobile capability to assign and track assets throughout the United States and its territories, particularly as it assists local, regional and national relief efforts. National Guard logisticians will be able to access the ITV and feed all relevant tracking information in their own decision-support software to know what's where and what's coming.

The contracts with the National Guard demonstrate the growing need to rapidly and efficiently track critical materiel throughout their own facilities and into austere environments where there is little or no available communications or power infrastructure, said David Stephens, general manager of Savi's Public Sector. There's a force multiplier effect here since the National Guard--and potentially other civilian agencies�can leverage an off-the-shelf solution that links with the DoD's existing communications network.�

UK number two in RFID market

Research says US leads in number of sites using technology

Lisa Kelly, Computing, 20 Nov 2006

The UK is second only to the US in its adoption of RFID, according to a global study of the technologys take-up.

Consultancy IDTechExs study Hot Countries for RFID reveals that the UK holds second place by quantity, although not by money spent, where China lays claim to the number two spot.

But the gap between the number one and two spot is huge - the US had over 800 RFID implementations, while the UK has under 300.

Apart from being the greatest adopter with the largest number of cases of RFID in action, orders in the US are often the worlds largest by value.

Peter Harrop, chairman of IDTechEx, said: The reason why the UK is so high up the league by number of cases is because we've got the largest city in Europe with 7.2 million Oyster cards and in the round we are doing a bit of everything from healthcare, where babies and mums are tagged, to leisure applications, such as tagging runner's shoes in marathons.

'Our military force is also bigger than any other in Europe and we are using RFID to tag vehicles, trailers and missiles, or anything with a value of over 3,000,' he said.

Although the UK lags in terms of money spent, this could all change for the wrong reasons if the UK adopts a national identity card scheme based on RFID technology, says Harrop.

Considering China's national identification card scheme is going to cost $6bn by 2008 and they have 900 million people to tag, the UK is talking about a $15bn scheme and planning for an over-spend for only 60 million people which is poor value for money. We could become the biggest spender or number two to the US because of spending money on RFID like drunken sailors, he said.

Wal-Mart Backs RFID Technology

Will require suppliers to use 'smart' tags by 2005

Jaikumar Vijayan and Bob Brewin

Wal-Mart Stores Inc. last week said it plans to require its top 100 suppliers to put radio-frequency identification tags on shipping crates and pallets by January 2005, a move that's likely to spur broader adoption of the technology because of Wal-Mart's market clout.

However, at the Retail Systems 2003/VICS Collaborative Commerce conference here, IT managers and technology vendors alike said that RFID devices still need to overcome major manufacturing, pricing and standardization hurdles before widespread usage can begin.

Wal-Mart's move is expected to result in the deployment of nearly 1 billion RFID tags with embedded electronic product codes (EPC) for tracking and identifying items at the individual crate and pallet level, said Pam Kohn, vice president of the Bentonville, Ark.-based retailer's global supply chain operations.

But even Wal-Mart's initial RFID effort will be narrowly focused. Although RFID tags can gather and track a variety of data related to products, materials and more, Kohn said Wal-Mart will concentrate at first on using the technology to improve inventory management in its supply chain.

"We're still determining all the benefits," Kohn said. "We don't want to overburden ourselves." She added, though, that even if Wal-Mart were to collect no new data with the RFID tags, the efficiency and accuracy with which items can be tracked would be huge benefits in and of themselves.

RFID uses low-powered radio transmitters to read data stored in tags that are embedded with tiny chips and antennas. Proponents of the technology say such "smart" tags can store more detailed information than conventional bar codes, enabling retailers and manufacturers to track items at the unit level.

RFID tags have been available for several years, but adoption has been slow because the tags are more expensive than bar coding and because standards are lacking to ensure interoperability between tags and data readers.

Gary Robertson, executive director of global infrastructure at Delphi Corp., a Troy, Mich.-based maker of automotive electronics systems that uses RFID devices in its manufacturing operations, said Wal-Mart's decision to deploy the technology "will legitimize it and push it into the mainstream."

"The fact that the largest company in the world is publicly adopting EPC open standards should give companies confidence that the day of a single, interoperable RFID system is close at hand," said Kevin Ashton, executive director of MIT's Auto-ID Center in Cambridge, Mass.

The Auto-ID Center is working with Uniform Code Council Inc. (UCC) in Lawrenceville, N.J., and EAN International in Brussels to develop a standardized EPC format for storing data on RFID tags. That effort got another boost last week when Microsoft Corp. said it will join AutoID Inc., a not-for-profit joint venture set up by UCC and EAN to oversee the still-evolving standards.

Cost Possibly $50M

Wal-Mart didn't say how much the effort would cost it or its suppliers or whether new systems will be needed to support the technology. But even at the 5-cents-per-tag price that Wal-Mart said it plans to seek from vendors, the cost of the tags alone would total $50 million.

According to the Auto-ID Center's Web site, RFID tags typically cost at least 50 cents each, and RFID readers sell for $1,000 or more. Big companies could require thousands of readers for all their factories, warehouses and stores, the site says.

Wal-Mart isn't the only retailer putting its faith in RFID. London-based Marks & Spencer PLC, one of the U.K.'s largest retailers, is rolling out RFID technology in its food supply chain operations. The project involves putting 13.56-MHz RFID tags on 3.5 million new plastic trays used to ship products, according to Keith Mahoney, the company's food logistics controller.

Marks & Spencer has subjected the tags to a variety of temperature, moisture and distance tests before deploying them, Mahoney said during a presentation at the conference. Although the lack of common RFID protocols and standards remains an issue, "we could not allow the lack of them to hang up the project," he added.

RFID can yield "a huge benefit" for some companies, said David Hutchins, senior director of enterprise systems at Kraft Foods North America Inc. in Northfield, Ill., and a member of the AutoID board. However, Kraft is still evaluating the technology's potential value in its own supply chain. "The first thing is figuring out the business case," Hutchins said.

Epassports with RFID chips now a reality

CYBERDUDE | Puneet Mehrotra

August 17, 2006

The US Department of State on Monday started to issue electronic passports (e-passports) equipped with RFID-chips.

USA gets RFID passports

RFID passports have been much talked about. Germany uses RFID in passports to help border officials guard against forgeries and automate the processing of international visitors. The US has decided to finally get epassports.

On Monday the US Department of State started to issue electronic passports (epassports) equipped with RFID chips. According to reports the US government has placed an order with a California company, Infineon Technologies North America for smart chip-embedded passports.

The Associated Press said the new US passports include an electronic chip that contains all the data contained in the paper version name, birth date, gender, for example and can be read by digital scanners at equipped airports. They cost 14 per cent more than their predecessors but the State Department said they will speed up going through customs and help enhance border security.

Views against ePassports

I was reading Dan Goodwin's article, an AP Technology writer, where experts warned against epassports.

The article said, "Electronic passports being introduced in the US and other countries have a major vulnerability that could allow criminals to clone embedded secret code and enter countries illegally, an expert warned. A demonstration late on Friday by German computer security expert Lukas Grunwald showed how personal information stored on the documents could be copied and transferred to another device."

The Next Generation security

Don Goodwin article on experts warning on security was definitely informative. I even agree with Lukas Grunwald. But the fact remains the world isn't the same any longer. Terror has acquired a totally new definition and surveillance has to move on to new generation security.

RFID promises just that.

Of course no security system is foolproof and RFID passports are no different. The terror geeks must be already working to get past or get into the new passport system. But the checks and balances and the surveillance, which the new passports will provide are unmatched by traditional methods. My guess is a few teething problems and maybe even a few loopholes later the RFID passport system promises to be far superior to the traditional system.

RFID - a technology of impact

The kind of impact RFID would have on human history is beyond words. Chances of its misuse too are high. An innovative or a destructive mind is all that would be required and super benefits or super chaos is what we are going to see in the days of the RFID. The benefits are absolutely too huge to be ignored.

In these terror times RFID offers a security solution that is viable and implementable

Speed through the checkout with just a wave of your arm

Timesonline.co.uk | Valerie Elliot

It may sound like a sci-fi fantasy but shoppers may one day be able to pay their grocery bills using a microchip implanted in their body.

The idea is already catching on with today's iPod generation. According to research released today by the Institute for Grocery Distribution (IGD), a retail think-tank, almost one in ten teenagers and one in twenty adults are willing to have a microchip implanted to pay shop bills and help to prevent card or identity fraud and muggings.

A quick scan of the arm would connect immediately to bank details and payments could be made swiftly. Such microchips are already used in cats, dogs and horses. They are used in cattle and sheep so that consumers can trace their food from farm to plate and are also being used to help to combat drugs counterfeiting.

But now the retail industry is looking at body chips among a range of biometric payment methods, including fingerprint and iris recognition. So far the only example of a human body chip being used is at the VIP Baja Beach Club in Barcelona, where people wear bikinis and shorts and there is nowhere to carry wallets and purses.

The club offers clients a microchip, injected in the arm, which gives them access to certain areas of the club and acts as a payment method at the bar. This chip, made by the VeriChip Corporation, is a glass capsule about the size of a grain of rice, which sits under the skin. It carries a ten-digit personal number that can be linked to a person's bank account, and has been a success at the club.

Geraldine Padbury, senior business analyst at IGD, accepts that many consumers will have concerns about their privacy, but says that teenagers, the next generation of shoppers, will have far fewer concerns about using the body chips.

She said: "With teenagers happy to use MySpace and blogs to share details of their private lives, there may be less concern surrounding privacy than for other generations."

However, she believes that supermarkets will look at using fingerprint and iris recognition for the immediate future. One in five teenagers and one in nine adults in the study made clear that they would like to pay using these biometric methods. These methods were more popular than paying by mobile phone because of concerns about the high level of mobile phone theft.

There is already a pay-by-touch experiment under way at the Midcounties Co-operative in Oxford, where a finger scan is linked to a bank account. This system is used by more than 2.3 million shoppers in the US and also allows them to cash cheques in stores. Fingerprint recognition is used at Ben-Gurion airport in Israel, rather than making passengers stand in a check-in queue.

The research also gives supermarket bosses a clear warning that they will have to speed up shopping trips. In the survey, 66 per cent of teenagers and 62 per cent of adults said that they wanted less staff involvement and more self-scanning of goods. They wanted staff only to help to pack bags or fetch forgotten items.

About 16 per cent of teenagers and 12 per cent of adults wanted navigation systems on trolleys to help them round the store. Such a system is already being used at the Metro Future store in Rheinberg, near D�sseldorf. Shoppers connect their loyalty card to a computer attached to the trolley. Details are then displayed of goods purchased last time as well as special offers and where to find the items.

Here's two examples of Rfid Companies with links provided

Speedpass

is a "contactless" payment system that provides members with a quick and easy way to pay for purchases at participating Exxon and Mobil stations nation-wide. Speedpass is easier and more secure than using a credit card. No more waiting for authorizations and signing receipts. No more searching for cash and waiting for change. To use it, simply wave your Speedpass key tag across the area of the gasoline pump, convenience store terminal, or car wash kiosk that says "Place Speedpass Here".

Speedpass automatically -- and immediately -- communicates your payment preferences. It knows what credit or debit card you wish to use. Speedpass even knows whether or not you want a receipt.

Speedpass

Digital Angel Corporation develops advanced RFID and GPS technologies that enable rapid and accurate identification, location tracking, and condition monitoring of high-value assets. Applications for our products include identification and monitoring of pets, humans, fish and livestock through our patented implantable microchips as well as message monitoring of aircraft in remote locations through integrated GPS and geosynchronous satellite communications systems.

Digital Angel

|